Introduction

Automatic sample changers, autotunable probes, automatic shimming and locking routines, automation software and scripts have been used in solution NMR for decades. They allow us to spend less time in NMR laboratories, make a good use of nights and weekends, and maximise the number of samples to be measured. For example, a student of organic chemistry can set up a series of basic 1D and 2D NMR experiments to be collected on a series of their samples and go back to their synthetic lab. I would like to explain that automation and high throughput in solid-state NMR have become possible and how. In the previous post, I focused on automatic sample changers and sample exchange. I will focus on automatic tuning and matching, sample spinning and temperature control below.

Why should you care and read this short post? If you are already a user of solid-state NMR, but you rather rely on manual operation, you may find useful tips on automating and increasing throughput. If you rather consider using solid-state NMR for the very first time and you have heard how difficult solid-state NMR is, you may realise that the automation hardware and software make solid-state NMR easier for you.

What hardware is required for automation and high throughput in solid-state NMR?

Automatic tuning and matching

NMR probes need to be ‘tuned and matched’ before running experiments. This basically means adjusting the probe to the frequencies of nuclides to be irradiated and the sample inside the probe. The vast majority of solution NMR probes are autotunable nowadays. In contrast, autotunable solid-state NMR probes have become available only recently. The JEOL AUTOMAS probe mentioned in the previous post supports Auto Tuning units (Fig. 1) and is autotunable.

Figure 1. JEOL Auto Tuning unit for ECZ Luminous spectrometers.

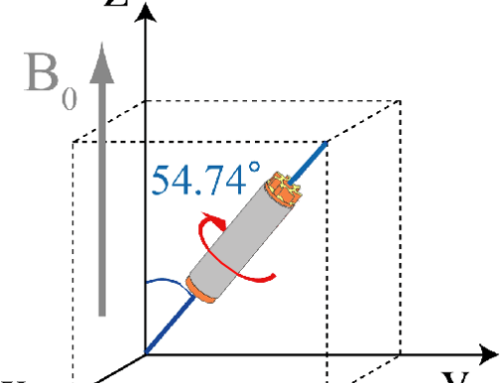

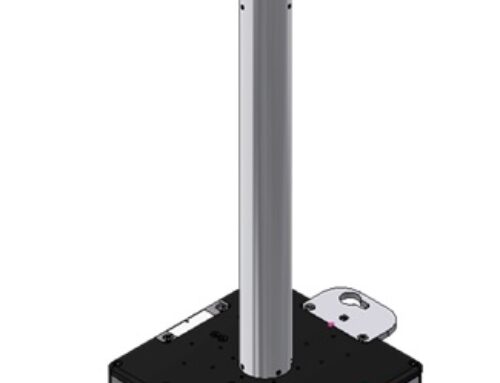

Automatic sample spinning

Liquid samples are spun by blowing compressed gas onto the spinners. Solids rotors are rather spun by blowing compressed gas, usually air or nitrogen, onto them. They have a spinning cap which acts as a small turbine. Magic Angle controllers (Fig. 2) automatically and very precisely adjust the pressure of bearing and driving gas to reach and keep the desired spin rate. In addition to that, these units also allow us to protect the internal parts of solids probe from overheating. Finally, recent generations of MAS CONTROLLER units (Fig. 2) support the JEOL AUTOMAS probes and switch the stator from the vertical to the Magic Angle position.

Figure 2. JEOL MAS CONTROLLER for ECZ Luminous spectrometers.

Automatic temperature control

You may sometimes want to run your NMR experiments at high or low temperature. This has become standard both in solution and solid-state NMR. The probes typically have in-built electric heaters, and hence sample heating is straightforward. Sample cooling is possible by connecting an electric cooling unit or a source of cold gas such as a dewar with liquid nitrogen to the probe. Temperature control units (Fig. 3) automatically adjust heater’s output and regulate flow rate.

Figure 3. JEOL temperature control unit for ECZ Luminous spectrometers.

Conclusions

As I have shown in this and previous post, the following hardware makes automation and high throughput in solid-state NMR possible:

- Automatic sample changer

- Solid-state NMR probe supporting automatic sample exchange and automatic tuning and matching

- Automatic tuning unit

- Automatic Magic Angle Spinning (MAS) controller

- Variable temperature control unit and accessories (optional)

And why not try JEOL JASON software for yourself and discover how its advanced data processing and analysis tools make it easy to get great results from solid-state and many other NMR datasets?

If you wish to know more about JEOL ECZ Luminous NMR spectrometers and JEOL AUTOMAS probes, click the links. In addition, a brochure on JEOL solid-state NMR products and applications can be downloaded here.